At GB Electronics, our electronics product testing and firmware programming service ensures every assembled product is validated, configured, and ready to perform from the moment it leaves our facility. Based in West Sussex, we support OEMs and technology firms in industrial automation, medical, defence, and IoT sectors.

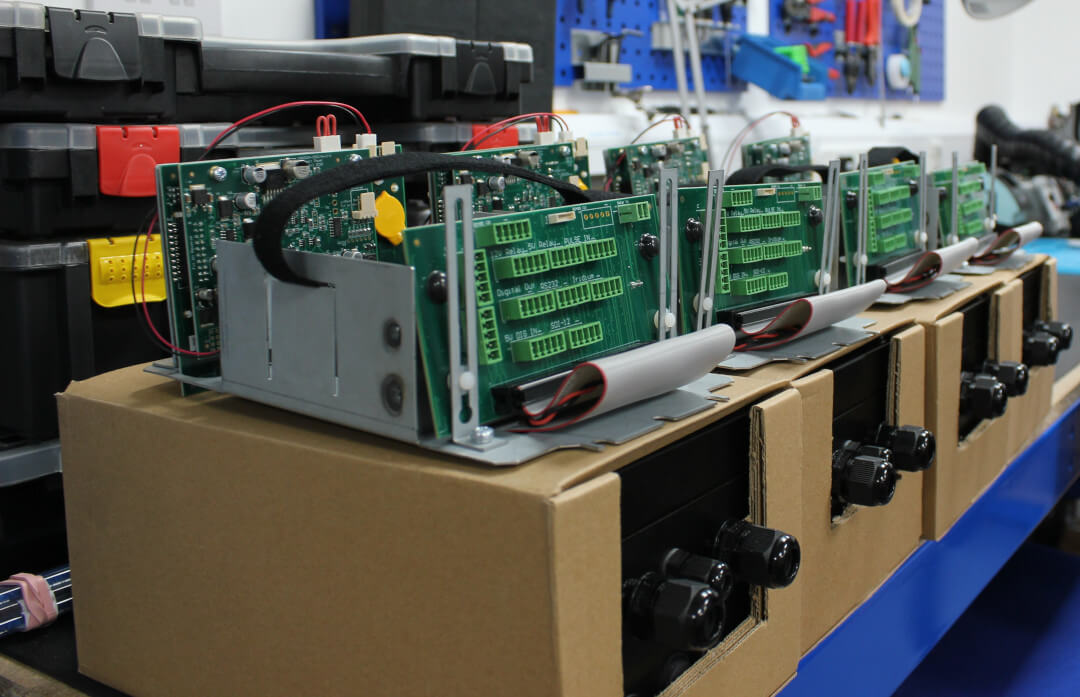

Our experienced team handles firmware programming, product configuration, and functional validation, supported by bespoke test jigs, automated programming stations, and ISO 9001-certified QA protocols.

We offer:

Why Choose GB Electronics for Electronics Testing & Programming?

With decades of experience in embedded systems, our team delivers programming and test workflows tailored to your product's architecture, communication protocols, and market requirements. We support a wide range of interfaces, including JTAG, USB, SWD, and UART, as well as firmware formats such as HEX, BIN, and ELF.

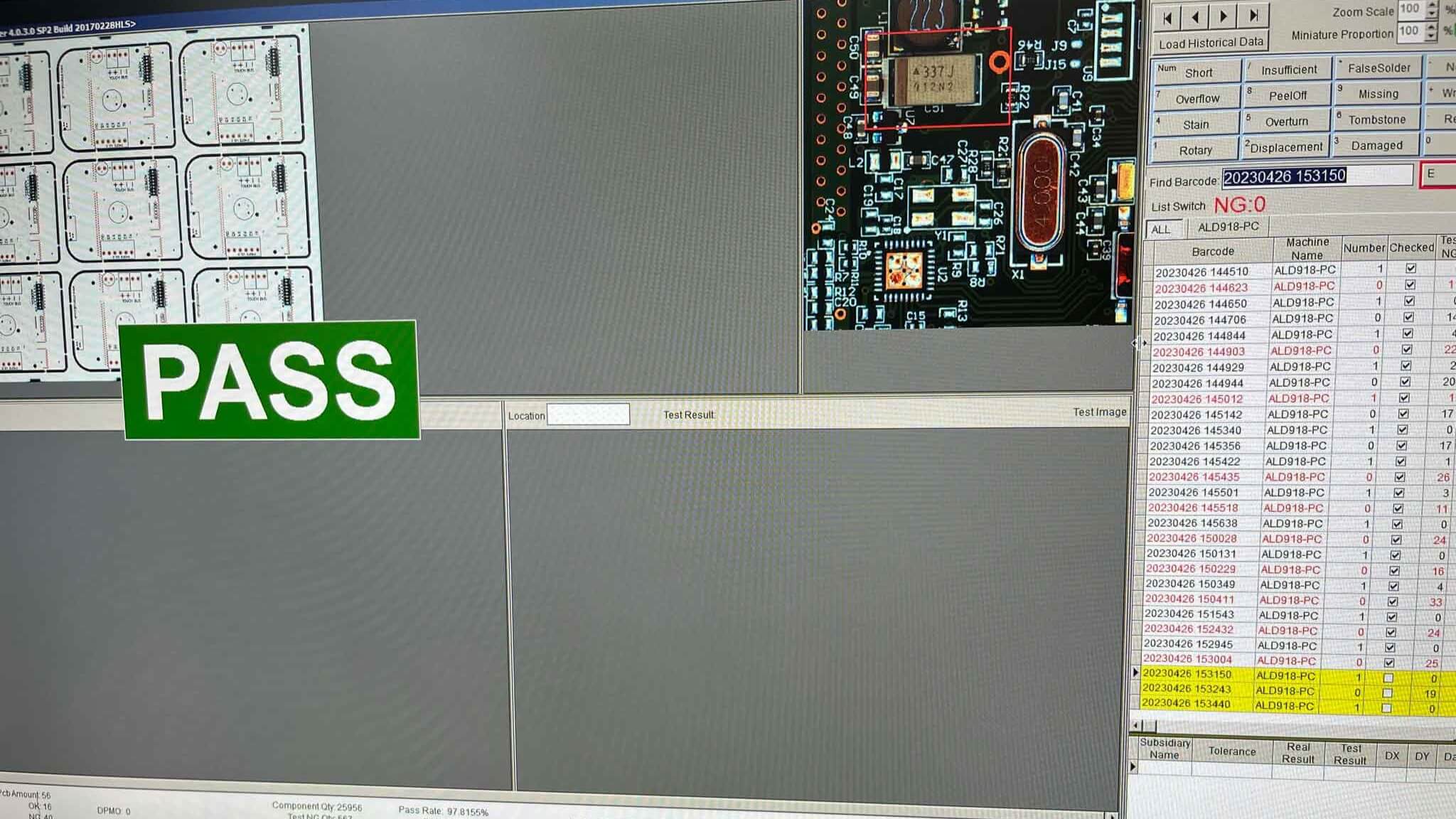

Our test environments simulate real-world usage, with pass/fail thresholds tailored to your specific requirements. Testing is logged and traceable, helping meet regulatory demands in high-reliability sectors. By embedding QA into production, we reduce field failures, speed up time to market, and enhance consistency.

Programming and testing are embedded within our contract manufacturing process, not bolted on after the fact. Whether we're building your product from the ground up or testing client-supplied PCBs, our workflow ensures consistent quality from prototype to final delivery.

We collaborate with your engineering team to align on firmware loading, product setup, and system-level testing. Our structured approach accelerates delivery timelines and reduces the risk of errors, especially important for products in regulated or safety-critical environments.

During early-stage development, we provide adaptable setups for rapid iteration and test validation. As your product scales, we develop dedicated jigs, automated test routines, and data capture systems that ensure production consistency and traceability.

We support seamless scaling from single units to high-volume runs—all tested and documented under our ISO 9001-certified QA system.

We integrate directly into your embedded architecture, offering both standalone firmware programming and full embedded development support. Services include:

All programming is verified before test and release, ensuring zero-configuration delivery.

Our custom test jigs validate digital/analogue I/O, sensor data, displays, and power systems in real-world conditions. We log every result, ensuring full traceability for audits, compliance, and support.

Automated pass/fail routines streamline inspection and eliminate operator variability. Every test follows a defined, documented process, tailored to your product's unique needs.

All services are delivered in-house at our West Sussex facility as part of our turnkey electronics manufacturing solution. We serve:

Our structured processes reduce friction, ensure repeatability, and keep your products compliant and consistent at scale.

Tell us about your project

Ready to embark on your next project? Contact GB Electronics today and let us discuss how we can assist you in creating efficient, compliant, and innovative electronic products. Reach us at +44 (0) 1903 244 500 or email us at info@gbelectronics.com